Industry Insights

Ayurvedic Tablet Manufacturer: How Brands Scale Without Compromising Quality

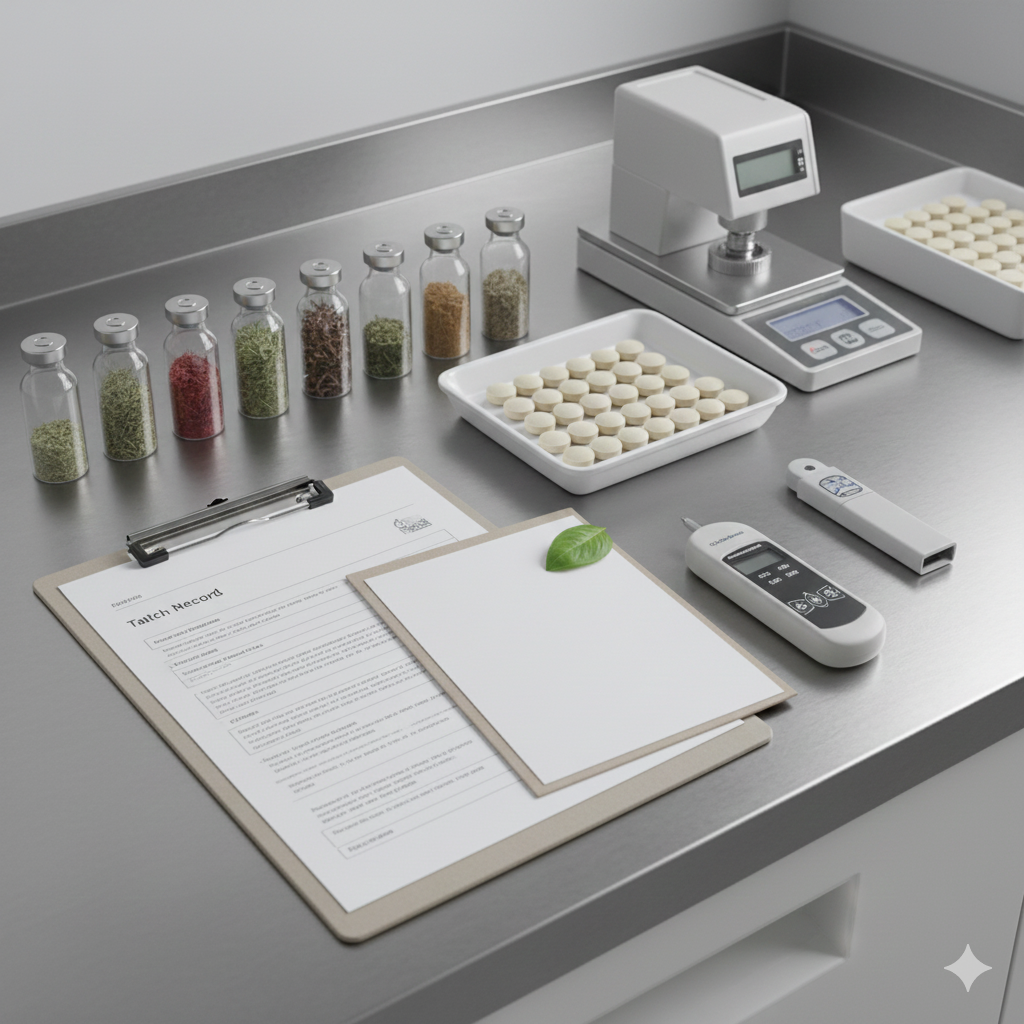

If you’re searching for an ayurvedic tablet manufacturer, you’re likely looking for two things: reliable batch-to-batch consistency and a process that supports your brand’s growth. Tablet formats remain one of the most preferred dosage forms because they are easy to pack, store, ship, and scale. At Space Organics, we approach tablet projects with a practical manufacturing mindset — feasibility first, then sampling, then stable bulk production, and finally packaging built for real-world logistics. This reduces rework, controls timelines, and helps brands launch and expand with confidence.

Ayurvedic Tablet Third Party Manufacturing: What It Really Means (And What You Should Ask)

Ayurvedic tablet third party manufacturing means you own the brand and positioning, while the production workflow is managed by a manufacturing partner. The most important part is not only tablet compression — it is building a repeatable system: feasibility, sampling, packaging alignment, bulk scheduling, and release documentation. Before finalizing a partner, clarify your pack format (bottle/blister), MOQ expectations, handling needs, and sampling timelines. A clear brief early on saves weeks later.

Herbal Tablet Contract Manufacturer: Choosing a Partner for Long-Term Production

Choosing a herbal tablet contract manufacturer is about long-term repeatability. Brands that scale smoothly are the ones that lock the process early: sampling → approvals → production scheduling → packaging checks → dispatch planning. Packaging decisions matter — blister vs bottle, induction sealing (as applicable), cartons and shipper strength affect breakage, returns, and customer experience. Start by sharing tablet type, pack size, MOQ and delivery timeline.

Third Party Tablet Manufacturing Company: A Simple Checklist for Faster Quotation

For faster quotation, keep your requirement clear: tablet type, pack configuration (bottle count or blister layout), MOQ, artwork status, and target delivery location. A complete RFQ helps plan correct line scheduling and packaging workflow early, which reduces timeline surprises.

Tablet Manufacturing for Ayurvedic Brand: Build Trust With Process, Not Promises

In competitive markets, operational excellence becomes your advantage: consistent batch outcomes, packaging readiness, and documentation discipline. A stable workflow typically follows: brief → feasibility → sampling → packaging alignment → bulk scheduling → QC release → dispatch planning.